Safety Manual for EVS-XCR - Safe Torque Off (STO)

Revision History

Rev. | Date | Description |

|---|---|---|

A | First official release of the document. | |

B |

| Updated during Functional Safety certification. |

C |

| Company Information added |

Scope

This document defines the EVS-XCR Safety Specifications and the Integration Requirements that must be fulfilled to guarantee Functional Safety.

Contact Information

Novanta Technologies Spain S.L.

C/ Avila 124, 2-B

08018 Barcelona

Spain

Telephone: +34 932 917 682

E-mail: hello@ingeniamc.com

Web site: drives.novantamotion.com

Safety Concept

The Safe Torque Off (STO) is a functional safety system that prevents motor torque in an emergency event while Everest S XCR remains connected to the power supply. When STO is activated, the power stage is disabled by hardware and the drive power transistors are disconnected, no matter what control or firmware does. The motor shaft will slow down until it stops under inertia and frictional forces. Although not common, in the event of a failure of the power stage during an STO situation, the maximum expected motor movement with torque can be up to 180º electrical degrees. The system must be designed to avoid any hazard in this situation.

If the STO inputs are not energized, the transistors of the power stage are turned off and an STO fault is notified. In order to activate the power stage, and therefore allow the motor operation, the two STO inputs must be energized (high level, typically 5V to 24V). STO inputs should not be confused with a digital input configured as enable input, because enable input is firmware controlled and does not guarantee intrinsic safety as it can be reconfigured by a user.

In order to ensure redundancy and safety, the Everest S XCR includes 2 separate STO inputs that must be activated or deactivated simultaneously (maximum tABN_LATCH_MAX mismatch). A difference of state between STO1 and STO2 inputs will be interpreted as an abnormal situation after tABN_LATCH_MAX the drive will be latched in a fault state. A power supply reset is necessary to remove this STO abnormal error.

Safety Specifications

Safety Function Specification | Value | |

|---|---|---|

Standards compliance |

| |

Safety function | Safe Torque Off (STO) | |

Safety relevant parameters according to EN 61508:2010 | Safety integrity level | SIL3 |

PFH | 1.53 x 10-9 1/h | |

SFF | > 99 % (High) | |

Safety relevant parameters according to EN ISO 13849-1:2015 | PL | e |

Category | 3 | |

DC | 99% High | |

MTTFd | ≥ 100 years (High) | |

Safety Function Reaction Time | t < 6.3 ms The Safety Function Reaction time is measured as the time since one of the STO inputs (STO1 or STO2) goes below 1.1 V and the STO function actuates (power transistors deactivated). | |

Fault Reaction Time | t< 33 ms The worst-case fault reaction time is on the event of a 5V DC/DC supply overvoltage. | |

High-demand mode | The EUC (Equipment Under Control) is considered as a high-demand or continuous demand mode system. | |

Mission Time | The mission time of the EUC is of 20 years. | |

Diagnostic Time Interval | In order to guarantee the correct operation of the safety functions, the user has to check the STO function regularly, performing an STO External Diagnostic Test (see further information below). The diagnostic test interval is defined as a minimum of 1 activation per 3 months. | |

Interface and Integration Requirements

Functional Safety is only guaranteed within the following Integration Requirements.

Integration Requirement | Value | |

|---|---|---|

STO Interface electrical characteristics | Input pins | STO1, STO2 and STO_RET |

Number of independent channels | 2 | |

Type of Inputs | Isolated inputs (STO1, STO2) with common reference (STO_RET). ESD protected with input current limit to reduce power. See schematics next. | |

Maximum input LOW level (VIL) | 1.1 V or open (below this value the STO is ACTIVE, no torque can be applied to the motor) | |

Minimum Input HIGH level (VIH) | 3.6 V (above this value the STO input is inactive, torque can be applied to the motor) | |

Maximum absolute ratings | 24 V SELV (maximum OVP 26.4V (110%); maximum failure voltage 60 V) | |

Input current | 2.5 mA typ / 5 mA max per channel | |

Isolation Level | > 4 GΩ, 500 Vrms, 1000 VDC | |

ESD, EFT and Surge Immunity | IEC 61000-4-2 (ESD) ± 15 kV (air), ± 8 kV (contact), IEC 61000-4-4 (EFT) 40 A (5/50 ns), IEC 61000-4-5 (Surge) IPPM > 8 A | |

STO Interface timing characteristics | STO activation time (Safety function Reaction Time) | t < 6.3 ms |

STO deactivation time | t < 2ms | |

Minimum, non-detected STO short pulse | t < 400 µs The Safety controller can transmit short pulses to STOx inputs for diagnostics purposes. These pulses will be ignored by the safety circuit and will not stop the power stage. | |

Abnormal STO diagnostic time | tABN ≤ 6.3 ms (Activation STO) | |

Abnormal STO latching time | tABN_LATCH_MAX ≤ 3.4 s (Latching state, permanent activation of STO until power reset) | |

Power supply diagnostic time | 5 V over-voltage 33 ms, 5 V under-voltage 33 ms 3.3 V over-voltage 200 ns, 3.3 V under-voltage 8 ms | |

Logic Supply Voltage Range 1 | Logic supply must be provided to the system 24 V SELV (range from 8V to 26.4V; maximum failure voltage 60 V) | |

Power Supply Voltage Range 1 | 48 V SELV (range from 8V to 60V; maximum failure voltage 60 V) | |

Motor Type | STO safety function is only considered when the drive is controlling three-phase permanent magnet synchronous rotating motors. STO does not apply to DC brush motors. | |

Uncontrolled Motor Movement |

Uncontrolled Motor MovementIn the event of a failure in the power stage, the motor shaft may rotate up to 180º electrical degrees. It is responsibility of the customer to prevent any hazards related ot this unexpected motor movement. | |

Environmental Conditions for STO2 | Pollution degree | Pollution degree 2 with an IP54 enclosure installation. |

Over-voltage category | II | |

Altitude | < 2000 m above sea level. | |

Operating Temperature | -20ºC to 60 ºC | |

Storage Temperature | -40ºC to 100ºC | |

Vibration | 5 Hz to 500 Hz, 4-5 g. Test according to IEC 60068-2-6:2007-12: Test Fc | |

Shock | ±15g Half-sine 11 msec Test according to IEC 60068-2-27:2008-02: Shock | |

Diagnostics | Internal power supply voltage monitors. Differences between STO1 and STO2 cause abnormal fault. After tABN_LATCH_MAX a hardware latching condition disables the drive until power cycling. Status of STO1, STO2, STO_REPORT, ABNORMAL_FAULT, and SUPPLY_FAULT can be read from the communications. STO firmware notificationA STO stop is notified to the motion controller and creates a fault that can be read externally from any communication interface, however, STO operation is totally independent and decoupled from control or firmware. | |

EMC | Functional Safety has been tested according to IEC 61800-3:2018 procedures with the extended ranges of IEC 61800-5-2:2017. To fulfill the EMC requirements it is necessary the use of the following elements is required:

| |

1: Although the drive can operate in a wider range of voltages as can be seen in Product Description, the system cannot be considered safe outside this range.

2: The drive can operate outside the range as indicated in the Product Description, however, it will not meet Functional Safety requirements.

STO External Diagnostic Test

The operation of the STO diagnostic circuits must be verified at least once per 3 months. The following procedure details a method to verify the STO diagnostic circuits and the external wiring. If the procedure results are not the expected ones, safety could be violated and the system cannot be used. Note that it is responsibility of the customer to prevent any hazards related to motor movement during this proof test.

The procedure requires the Everest S XCR to be connected to a brushless motor.

Procedure Step | Action |

|---|---|

1 | Power on the drive. |

2 | Deactivate the Safety Function by providing:

|

3 | Transition to a normal operation state where the power stage can be enabled, and perform some motor movement. |

4 | Activate the Safety Function by providing:

|

5 | Remain in this state more than 3.4 seconds. |

6 | Deactivate the Safety Function by providing:

|

7 | Remain in this state more than 3.4 seconds. |

8 | Without performing a power reset, verify that the power stage can be enabled, and perform some motor movement. From Motionlab 3 software or communication channel, check that no Abnormal Fault appears. |

STO Operation States

The truth table of the STO inputs is shown next indicating the different states of the system:

Mode | State | STO1 status / level | STO2 status / level | Power stage status | STO report bit status | STO abnormal fault | State description | ||

|---|---|---|---|---|---|---|---|---|---|

Normal operation | STO Enabled | 0 | < VIL V | 0 | < VIL V | OFF | 0 | 0 | The system logic is powered, but the STO function is activated. Therefore, no torque can be applied to the motor. STO trip is reported to the MCU and to the safety circuitry. This is intended safe torque off with dual-channel operation. |

Torque enabled (STO inactive) | 1 | > VIH V | 1 | > VIH V | Can be enabled | 1 | 0 | The STO function is deactivated, and torque can be provided to the motor. The motor can run under firmware control. This is the normal operation state. | |

Abnormal operation | Abnormal STO | 0 | < VIL V | 1 | > VIH V | OFF | 0 | 1 | If any issue is detected on the dual-channel STO function (their state is different for a long period of time), an abnormal fault is active can be reported. This state avoids the application of torque to the motor. If this persists for > tABN_LATCH_MAX the STO will lock in FAULT state. To reset this fault a power cycle is needed. |

1 | > VIH V | 0 | < VIL V | OFF | 0 | 1 | |||

Abnormal STO Latched | x | - | x | - | OFF | NOR (STO1, STO2) | 1 | After > tABN_LATCH_MAX of abnormal STO active, the driver will stay in this state until the power supply cycle. | |

Abnormal Supply | x | x | x | x | OFF | x | x | If a voltage out of the limits is detected on the internal logic voltages, the system is conducted to a safe state, similar to power-off. Only if the safe logic voltages are recovered (usually after reparation or restart), the system can return to any other state. | |

STO1 and STO2 signals should always change at the same time with a maximum of tABN mismatch. This is necessary to have 2 channel redundancy and allow diagnostics, as a mismatch will cause an abnormal fault.

The logic level of an STO signal between VILV and VIHV is unknown. If supplied at unknown level, STO1 and STO2 could have different logic values and trigger an abnormal latching fault.

In order to ensure this, do not add big capacitors (> 1 µF) in parallel to the STO inputs as this may cause faults during activation or deactivation of the STO.

Les signaux STO1 et STO2 doivent toujours changer en même temps avec un décalage maximum de tABN . Ceci est nécessaire pour avoir une redondance à 2 canaux et permettre le diagnostic, car une discordance provoquera une anomalie de fonctionnement.

Afin de garantir cela, n'ajoutez pas de gros condensateurs (> 1 µF) en parallèle aux entrées STO, car cela pourrait provoquer des défauts lors de l'activation ou de la désactivation du STO.

Le niveau logique d'un signal STO entre VIL et VIH est inconnu. S'ils sont alimentés à un niveau inconnu, STO1 et STO2 peuvent avoir des valeurs logiques différentes et provoquer une anomalie de fonctionnement.

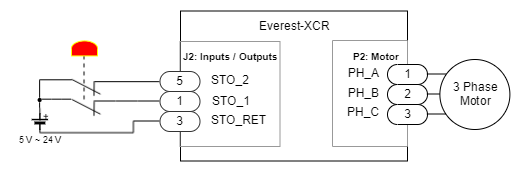

Application Examples

The following diagrams provide application examples, which could be further optimized or improved. For further circuit details or assessment, please contact Novanta.

The wiring of the recommended STO circuit is shown next. When using this circuit ensure the difference between STO1 and STO2 signals changing the state is less than tABN_LATCH_MAX to prevent an abnormal situation. When using various protective switches connect them in series.