Dynamic braking

Summit servo drives include a feature known as “Dynamic braking”, which is a method used for braking electrical motors. This process involves transforming mechanical energy into heat or electrical energy to decelerate and halt movement.

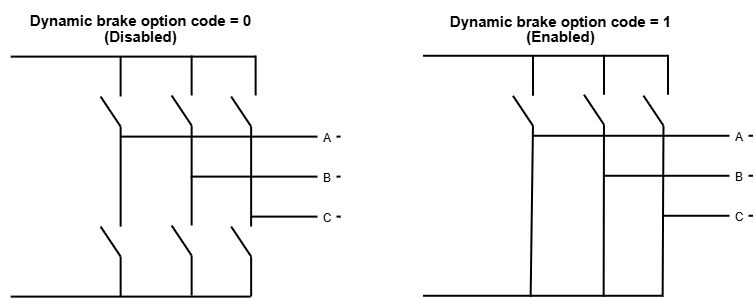

When dynamic braking is enabled, all PWM phases are shorted to GND when the power stage is disabled.

Dynamic braking can be configured using 0x262E - Dynamic brake option code

The motor will oppose brake when rotated if the power stage is disabled and Dynamic braking is enabled.

Disabling the power stage while dynamic braking is enabled and the motor is in motion may result in destructive operation due to high current induced in the transistors and motor.

Dynamic braking is designed to prioritize safe deceleration of the system in fault conditions. For this reason, overcurrent protections are not effective during dynamic braking, as fault conditions themselves trigger the dynamic braking. While it helps limit uncontrolled motion, it may result in component damage if current limits are exceeded. In such cases, drive or motor failure may occur as a trade-off to ensure braking safety.

The limits that could cause transistor failure during dynamic braking are the maximum continuous and peak phase current ratings specified in the product manual, and the derating should be taken into account for the safe limits.

Additionally, the motor's own current limits should be respected. If the motor's allowable phase current is lower than the transistor limits, exceeding the motor's ratings may result in motor damage, even if the transistors remain within safe operating conditions.

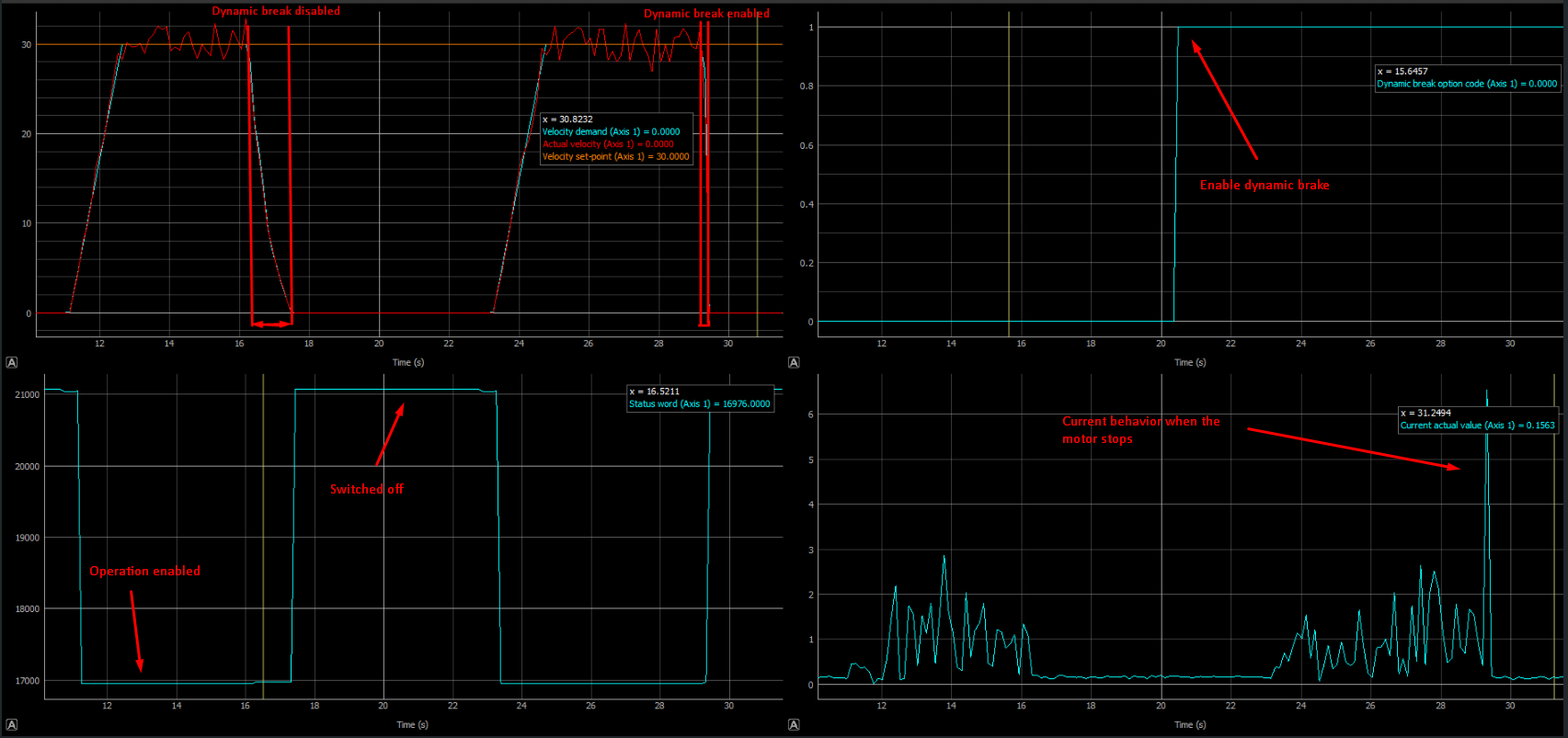

The graphs below illustrate the braking times of the motor with and without dynamic braking.