Product Description

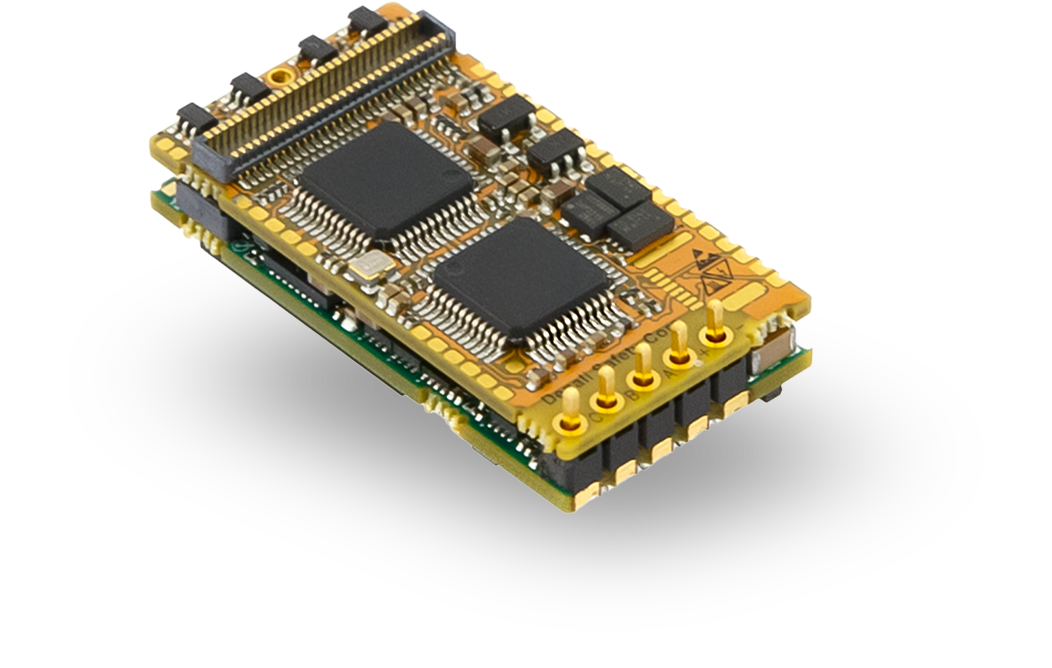

Denali Safe NET (DEN-S-NET-E) is a Functional Safety certified mid-power, highly integrated, low profile, digital servo drive intended to be plugged or soldered to an application-specific daughter board. The drive includes advanced Functional Safety features, like FSoE (Safety over EtherCAT) communication, Safe Stop and Safe Input as well as best-in-class energy efficiency thanks to its state-of-the-art power stage. The product is based on EtherCAT communication and can be easily configured with the Novanta Drives's free software MotionLab 3.

Main features:

Ultra-small footprint

Functional Safety: STO, SS1, FSoE; SIL3 and PLe certified

48 VDC, 5 A continuous

Up to 99% efficiency

Up to 50 kHz current loop, 25 kHz servo loops

20 kHz ~ 200 kHz PWM frequency

16 bit ADC current sensing

Supports Digital Halls, Quadrature Incremental encoder, Absolute BiSS-C encoder

Up to 4 simultaneous feedback sources

Full voltage, current, and temperature protections

Capable of controlling low inductance motors

Target applications:

Collaborative robot joints

Robotic exoskeletons

Medical applications

AGVs and AMRs

Humanoid robot joints

Page contents

Part numbering

Product | Ordering part number | Status | Image |

|---|---|---|---|

Denali Safe NET Functional Safety certified pluggable servo drive with EtherCAT communication. | DEN-S-NET-E | IN DESIGN |  |

General Label Identification |

|---|

Specifications

Electrical and Power Specifications

Minimum absolute DC bus supply voltage | 8 VDC |

|---|---|

Maximum absolute DC bus supply voltage | 60 VDC |

Recommended power supply voltage range | 8 VDC ~ 48 VDC SELV This voltage range ensures a safety margin including power supply tolerances and regulation during acceleration and braking. |

Internal drive DC bus capacitance | 5 µF ± 30% Note that DEN-S-NET uses ceramic capacitors. The capacitance value varies with DC bias and temperature. |

Logic supply voltages |

During an overvoltage fault, system could become non-operational, but safety function is maintained. |

Boot-up time | 4 s |

Minimum shutdown time | 500 ms |

Output reference voltages | 3.3 V ± 0.2%, 10 mA source / sink capability |

Maximum continuous phase current | 5 A 5 A can be obtained working at 48 V with an appropriate dissipation to keep the product plate under 70 ºC. See Thermal and Power Specifications below and Installation for further details. For disambiguation on current definitions please see Disambiguation on current values and naming for Ingenia Drives. |

Maximum peak phase current | 10 A @ 1 sec Notice that peak current could be limited by an automatic current derating algorithm. |

Maximum continuous output power | > 250 W |

Maximum DC Bus voltage utilization | 99.3% @ 20 kHz These values assume a Sinusoidal commutation and no load connected. |

Minimum Standby Consumption | 1.43 W typ. See details and conditions in Thermal and Power Specifications below |

Motion Control Specifications

Supported motor types | Rotary brushless (SVPWM and Trapezoidal) |

|---|---|

Power stage PWM frequency (configurable) | 20 kHz, 50 kHz (default), 100 kHz, 200 kHz |

Current sensing | 3 phase, shunt-based current sensing. 16-bit ADC resolution. Accuracy is ±2% full scale. |

Current sense resolution | 0.505 mA/counts |

Current sense range | ± 16.5 Apk (full range) |

Max. Current loop frequency (configurable) | 50 kHz Check the Power Stage & Control loops relationship section below. |

Max. servo loops frequency (position, velocity & commutation) (configurable) | 25 kHz Check the Power Stage & Control loops relationship section below. |

Feedbacks |

All feedback inputs are single-ended, 3.3 V logic levels. Check Safe Feedback section. The following feedback protocols are supported and can be used outside of the Functional Safety certification:

|

Supported target sources | Network communication: EtherCAT with Safety over EtherCAT (FSoE) |

EtherCAT |

Magnetic and capacitive connections supported |

Control modes |

|

Functional Safety Specifications

This product is certification pending. Until receiving the certificate any content in this section is subject to change.

DEN-S-NET-E Safe Communication (already implemented) | DEN-S-NET-E Safe Motion (future release) | |

|---|---|---|

Safety functions |

|

|

Safe Feedback | Not Supported | Safe Feedback with the combination of 2 individual encoders:

See Safe Feedback Combinations (DEN-S-NET Safe Motion - future release) for further details. |

Safety Integrity Level (SIL) according to IEC 61508:2010 | SIL3 | |

Performance Level (PL) according to ISO 13849-1:2015 | PLe, Cat. 3 | |

Safety Function Reaction Time | ≤ 25 ms | |

Safe inputs | 1 x Redundant Safe Input. Non-Isolated. Logic level (3.3 V and 5 V tolerant). Active-low. | |

Command Source |

| |

FSoE cycle time | ≤ 50 ms | |

Standards compliance | Targeted standards (certification pending):

| |

Safe Feedback Combinations (DEN-S-NET-E Safe Motion - future release)

The section below is relevant to the future implementation of the EVS-S-NET drive offering Safe Motion features.

This product is certification pending. Until receiving the certificate any content in this section is subject to change.

Denali Safe NET can provide advanced Safe Motion functions by using two individual non-certified encoders:

Feedback Combination | DEN-S-NET-E Safe Communication (already implemented) | DEN-S-NET-E Safe Motion (future release) | |

|---|---|---|---|

Safe Feedback 1 | Safe Feedback 2 | Safety Functions allowed | |

- | - | STO, SS1-t and SI | STO, SS1-t and SI |

BISS-C BP3 - Port 1 | BISS-C BP3 - Port 2 | N/A | STO, SS1-t and SI Safe Velocity Functions: SS1-r, SAR, SLS, SSR, SDI, SV Safe Position Functions: SS2-r, SS2-t, SOS, SLP, SLI, SP |

BISS-C BP3 - Port 1 | QEI | N/A | STO, SS1-t and SI Safe Velocity Functions: SS1-r, SAR, SLS, SSR, SDI, SV Safe Position Functions: SS2-r, SS2-t, SOS, SLP, SLI, SP |

Digital Halls | BISS-C BP3 - Port 2 | N/A | STO, SS1-t and SI Safe Velocity Functions: SS1-r, SAR, SLS, SSR, SDI, SV Safe Position Functions: SS2-r, SS2-t, SOS, SLP, SLI, SP |

Digital Halls | QEI | N/A | STO, SS1-t and SI Safe Velocity Functions: SS1-r, SAR, SLS, SSR, SDI, SV Safe Position Functions: SS2-r, SS2-t, SOS, SLP, SLI, SP |

Note: To guarantee enough diversity, the encoders must be of different technology or manufacturer.

Note: Other feedback combinations can be used for Motion Control purposes out of Functional Safety certification.

Environmental Conditions

Environmental test methods | IEC 60068-2 |

|---|---|

Case temperature (Operating) | -20 ºC to +70 ºC |

Ambient temperature (Operating) | -20 ºC to +60 ºC |

Case and Ambient temperature (Non-Operating) | -40 ºC to +100 ºC |

Altitude (Operating) | < 2000 m above sea level. |

Vibration (Operating and Non-operating) | 10 Hz to 150 Hz, 1 g |

Mechanical Shock (Operating and Non-operating) | ±5g Half-sine 30 msec |

Pollution degree | Pollution degree 2 with an IP54 enclosure installation. |

Over-voltage category | II |

Maximum Humidity (Operating) | up to 93%, non-condensing at 60 ºC |

Maximum Humidity (Non-operating) | up to 93%, non-condensing at 60 ºC |

Inputs/Outputs and Protections

General purpose Inputs and outputs | 2x non-isolated single-ended digital inputs - 3.3 V logic level. Can be configured as:

2x non-isolated single-ended digital outputs - 3.3 V logic level, 3 mA max. sink / source current. Can be configured as:

2x ±3.3 V ,16-bit, differential analog inputs for load cells or torque sensors. Can be read by the Master to close a torque loop. 1x 0.3 V ~ 3 V, unbuffered analog output. |

|---|---|

Safe Inputs | 1 x Redundant Safe Input. Non-Isolated. Logic level (3.3 V and 5 V tolerant). Active-low. |

Dedicated digital output | Dedicated 3.3 V digital output for Fault Signal status. |

Shunt braking resistor output | Configurable over any of the digital outputs (see above). Enabling this function would require an external transistor or power driver. |

Motor brake output | Dedicated, PWM-capable, 3.3 V digital output for driving a mechanical brake. Turn-on and turn-off times are configurable. Enabling this function would require an external transistor or power driver. |

Motor temperature input | 1x dedicated, 3.3 V, 12-bit, single-ended analog input for measuring motor temperature. NTC, PTC, RTD, linear voltage sensors, silicon-based sensors and thermal switches are supported. |

Protections |

The configurable protections are configurable up to the drive limits. In any case when the limits are reached, the drive is completely switched off with the current reduced to 0.

|

Over-current | An overcurrent device in series (i.e. fuse or similar) is needed with a rating of maximum x3 of the max current of the motor on the system and a minimum voltage rating of 60V Consider Vbus overshoots and reinjections to dimension the protection accordingly. |

Communication for Operation

EtherCAT | CANopen over EtherCAT (CoE) File over EtherCAT (FoE) Ethernet over EtherCAT (EoE) Failsafe over EtherCAT (FSoE) Magnetic and capacitive connections supported |

|---|

Mechanical Specifications

Dimensions | 33 mm x 17.6 mm x 9.5 mm |

|---|---|

Weight | 7 g |

Compliance

EC Directives |

|

|---|---|

Electromagnetic Compatibility (EMC) Standards |

|

Product Safety Standards |

|

Functional Safety Standards | See section Functional Safety Specifications |

Environmental Test methods | IEC 60068-2:

|

Thermal and Power Specification

Standby power consumption

The following table shows the standby power consumption when the Denali power stage is enabled.

Power supply voltage | Logic supply consumption (5V, 3.3V and Vmagn_ct) | Power stage DC bus consumption switching at 0 current | |||

|---|---|---|---|---|---|

EtherCAT (2 ports active) | 20 kHz | 50 kHz | 100 kHz | 200 kHz | |

8 V | < 1.4 W The measurement includes:

The measurements DO NOT include 100 mW corresponding to ethernet magnetics, not included in the Denali NET. | 0.007 W | 0.01 W | 0.03 W | 0.07 W |

48 V | 0.13 W | 0.32 W | 0.63 W | 1.25 W | |

60 V | 0.19 W | 0.46 W | 0.92 W | 1.83 W | |

Measurement environment

No feedbacks connected

No I/Os connected

Motor current is set to 0 (Voltage mode 0 V)

STO circuitry supplied at 3.3 V (consumption considered).

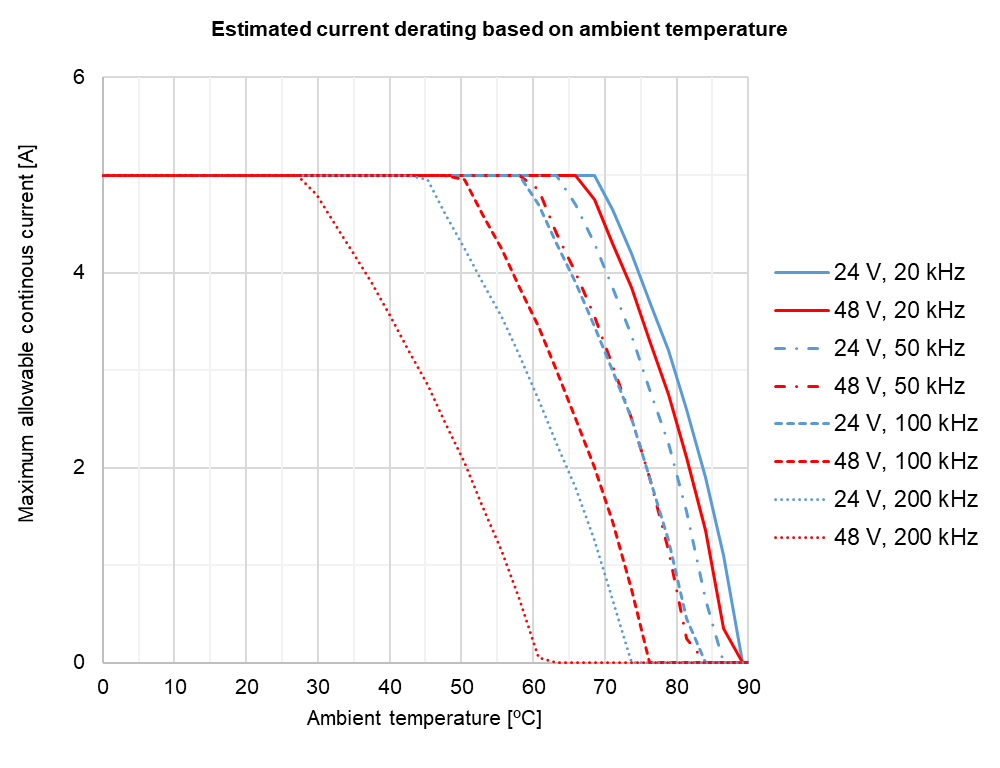

Thermal model

Current derating without plate

The following figure shows the maximum motor phase current at different ambient temperatures and operating points. The graph expresses the achievable current including the derating algorithm that limits the current-based operation conditions and the power stage temperature.

Notice that current is expressed in crest value for a 3-phase BLAC motor, not RMS. For further clarifications and conversion to equivalent RMS values please refer to Disambiguation on current values and naming for Ingenia Drives.

The following considerations apply to this measure:

Drive plugged into a 70 mm x 100 mm interface board.

Power pins are soldered to the board.

Convection dissipation to the air without forced airflow

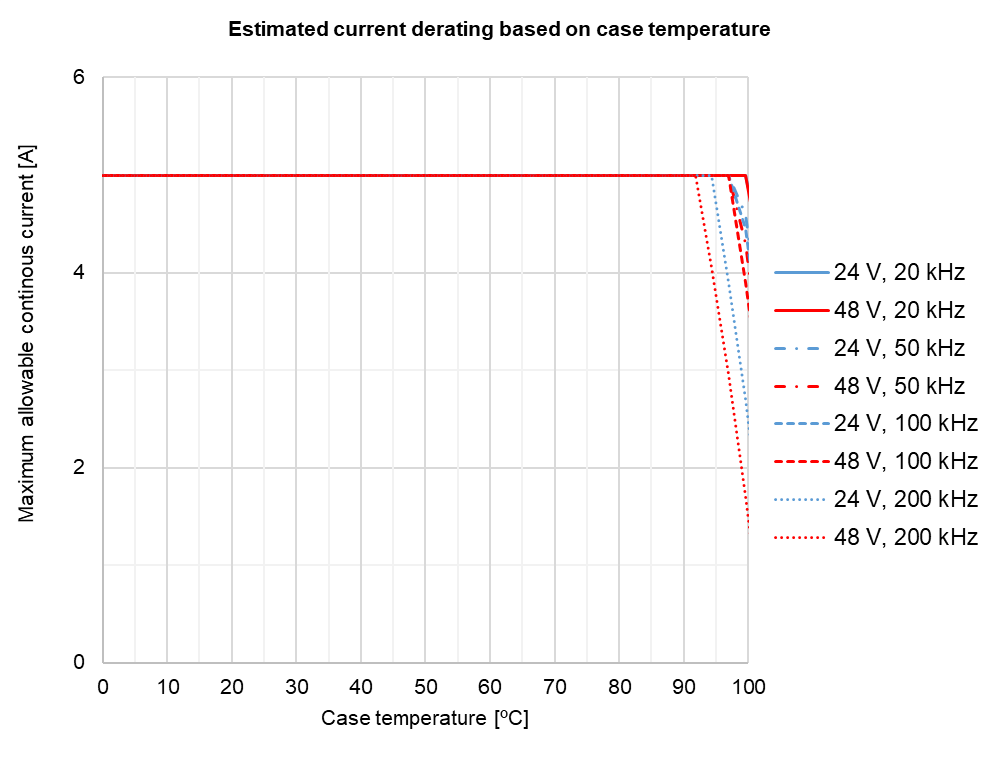

Current derating with case

It is highly recommended to use a case or heatsink to dissipate Denali Safe NET. See the Installation section for further details.

The following figure shows the maximum motor phase current when dissipating the Denali Safe NET with a case or heatsink. Results are referenced to the case temperature, providing a known interface for any system. The graph expresses the achievable current including the derating algorithm that limits the current-based operation conditions and the power stage temperature.

Notice that current is expressed in crest value for a 3-phase BLAC motor, not RMS. For further clarifications and conversion to equivalent RMS values please refer to Disambiguation on current values and naming for Ingenia Drives.

To ensure proper performance of Denali Safe NET, the case temperature should always be held below 85 ºC (Tc-max = 85 ºC).

Heat dissipation and heatsink calculation

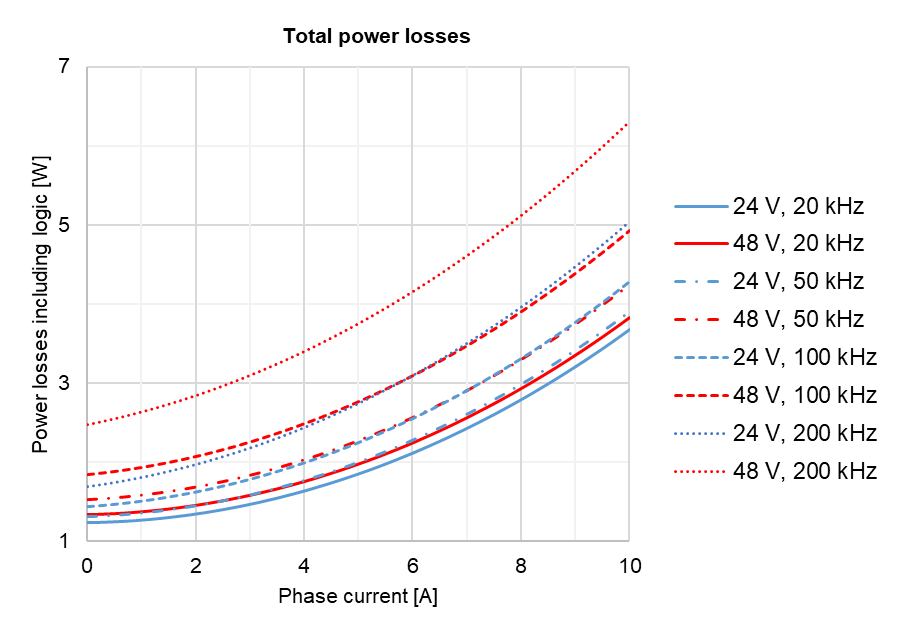

The following figure shows the total estimated power losses at different operating points. This includes logic supply which is an important contributor at low loads. As can be seen, lower PWM frequency and voltage lead to lower power losses.

Please, use the following procedure to determine the required heatsink:

Based on the voltage & continuous (averaged) current required by your application and Current derating graph determine the Case temperature Tc. Remember that Case temperature must always be below 85 ºC (Tc < 85 ºC)

For example: If the application requires 4 A @ 48V (100 kHz) the Tc maximum will be 85 ºC

Based on the voltage & continuous current required by your application and the Power losses graph determine the generated Power Losses PL to be dissipated.

For example: If the application requires 4 A @ 48V (100 kHz) the PL will be 2.5 W

Determine the Thermal impedance of the used thermal sheet Rth(c-h)

For example, a thermal sheet TGX-150-150-0.5-0, which has an estimated thermal impedance of Rth(c-h) = 0.2 K/W

Based on the ambient temperature and using the following formula determine the maximum thermal impedance to the air of the required heatsink Rth(h-a)

a. For example: If the application requires 4 A @ 48V (100 kHz) working at Ta = 25 ºC and we use a thermal sheet with Rth(c-h) = 0.2 K/W the required thermal impedance of the heatsink will be Rth(h-a) = 24.2 K/W

Power Stage & Control loops relationship

The power stage PWM frequency can be adjusted in 4 different frequencies. Each frequency has an associated rate for the control loops, as specified in the following table.

Power stage PWM frequency | Current loop frequency | Servo loops frequency (position, velocity, commutation & shunt) |

|---|---|---|

20 kHz | 20 kHz | 20 kHz |

50 kHz | 50 kHz | 25 kHz |

100 kHz | 50 kHz | 25 kHz |

200kHz | 50 kHz | 25 kHz |