Motion

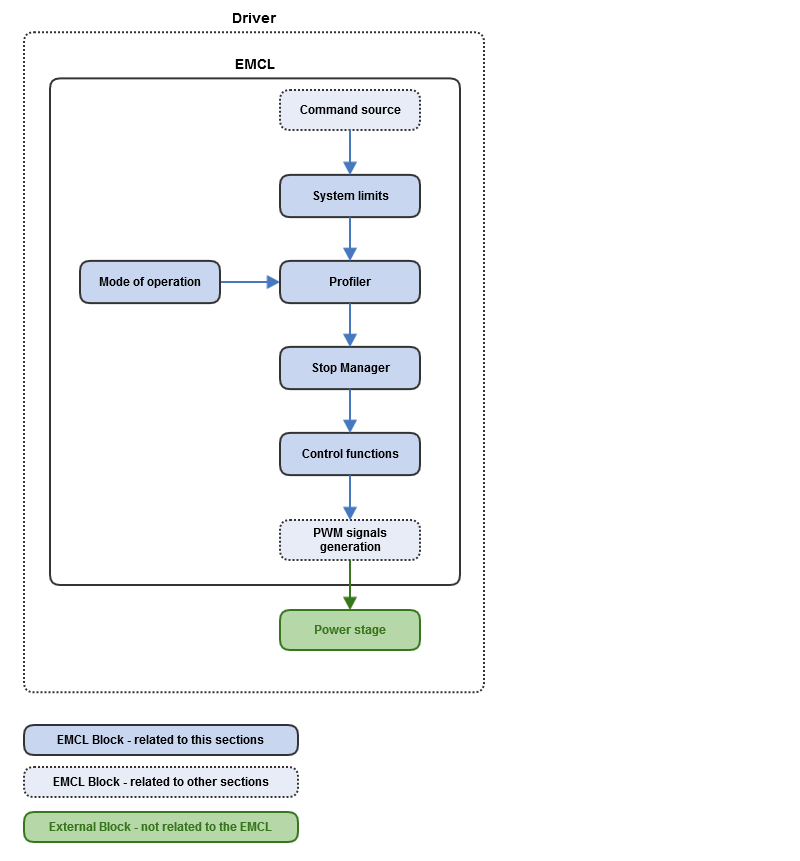

The motion subsystem comprises the EMCL elements which determine the system motion behavior. The motion subsystem is build from the basic 5 subsystems depicted below:

The system receives the target value for the magnitude that closes the control loop (position, velocity or torque) from the selected command source. Afterwards, this value is checked against the system limits, and modified if it exceeds the programmed range. The profiler uses the target value to recompute the adequate movement trajectory, and generates the demand values for the actuator, depending on the mode of operation selected. In the event that it is required, the movement trajectory is modified by the stop manager, whenever mechanical limits are to be exceeded. Finally, control functions convert the demanded value into the required electric motor effort.

Notice the difference between mechanical and system limits: mechanical limits imply the measurement of the actuator actual position through an external mechanical sensor like a switch, while system limits can be softer or more indirect (for instance, count-based, which does not provide hard information about the system exceeding its mechanical range or not), and can limit torque and velocity too.