Motor and shunt braking resistor

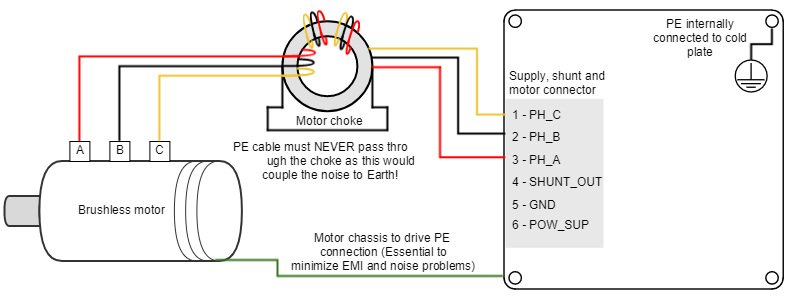

AC and DC brushless motors

Brushless motors should be connected to phase A, B and C terminals. Note that some manufacturers may use different phase name conventions (see Table below).

Phase name | Alphabetic | Numeric | UVW |

|---|---|---|---|

PH_A | A | 1 | U |

PH_B | B | 2 | V |

PH_C | C | 3 | W |

STO

Safe torque off inputs must be enabled in order to deliver power to the motor. If the Safe Torque Off inputs (Connector P3) are not connected an error will appear and the driver will not power the motor.

Common-mode choke

In order to minimize EMI that can affect sensitive signals, the use of a motor choke is highly recommended. The objective of the motor choke is to block the common mode current to the motor and cables. While using a separate choke for each phase could also work, the EMI reduction would be much lower than passing all the phases through the same choke.

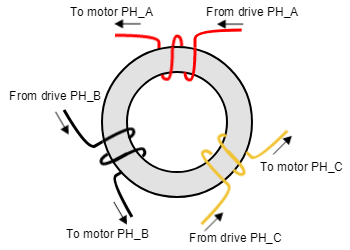

Proper three-phase motor choke wiring

In order to minimize the capacitive coupling of the motor wires, and therefore cancelling the effect of the common mode rejection effect, the choke has to be properly wired.

- An excessive number of turns causes a high capacitive coupling. Only 2 or 3 turns per motor phase are recommended.

- For reducing the coupling between phases, space the phases 120º apart. Start each phase wire in the same rotating direction, wrapping all phases clockwise or anticlockwise. This will add the common mode flux and increase its impedance.

- Remind that PE cable must NEVER pass through the choke as this would couple the noise to Earth.

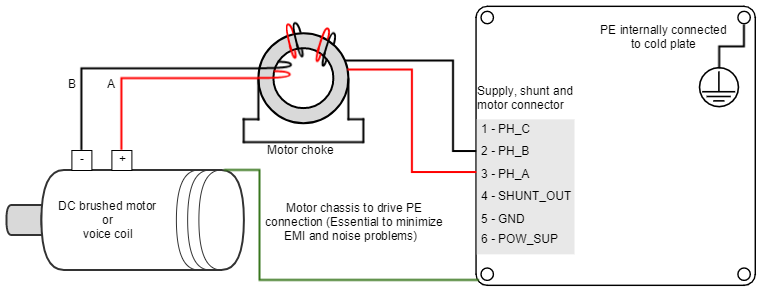

DC motors and voice coils actuators

DC motors and voice coil actuators are connected to phase A and phase B terminals. Phase C terminal is left unconnected.

Common-mode choke

In order to minimize EMI that can affect sensitive signals, the use of a motor choke is recommended. The objective of the motor choke is to block the common mode current to the motor and cables. While using a separate choke for each phase could also work, the EMI reduction would be much lower than passing all the phases through the same choke.

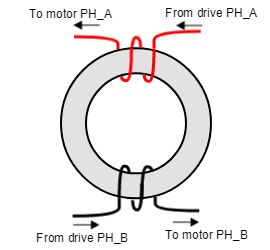

Proper DC motor choke wiring

In order to minimize the capacitive coupling of the motor wires, and therefore cancelling the effect of the common mode rejection effect, the choke has to be properly wired.

- An excessive number of turns causes a high capacitive coupling. Only 2 or 3 turns per motor phase are recommended.

- For reducing the coupling between positive and negative, space them 180º apart. Start positive and negative wire in the same rotating direction, wrapping both phases clockwise or anticlockwise. This will add the common mode flux and increase its impedance.

Motor wiring recommendations

Wire section

The minimum wire section is determined by the motor current. It is preferred to use wide section stranded wires to reduce impedance, power losses and ease the assembly. Following table indicates recommended section for the Titan Go Servo Drive:

| Connection | Minimum wire size | Maximum wire size |

|---|---|---|

| Stranded wire (preferred) | 8.4 mm2 (8 AWG) | 33.6 mm2 (2 AWG) |

| Solid wire | 8.4 mm2 (8 AWG) | 33.6 mm2 (2 AWG) |

Motor choke

In applications where electromagnetic compatibility is a concern or that must comply with the EMC standards, the use of an external common mode choke is necessary. Some choke wiring recommendations are:

- Place the choke as close to the drive as possible.

- Make sure the chosen choke does not saturate at the maximum operating phase current. If this happens, the choke temperature would increase rapidly.

- Only 2 or 3 turns of the motor cables to the choke are recommended for best performance. Doing more than 3 turns reduces choke effectiveness, as capacitive coupling between wires would bypass the choke effect.

- PE conductor should NOT pass through the choke.

- Avoid contact of the toroid core with a grounding point.

Next table shows a choke that fits the Titan Go Servo Drive specifications and has a great performance at low frequencies.

Type | Manufacturer | Reference |

|---|---|---|

| Ferrite toroid | Magnetics | ZJ49740TC |

| Ferrite toroid | Magnetics | ZJ49740TC |

Wire length

- The distance between the Titan Go Servo Drive and the motor should be minimized when possible. Short cables are preferred since they reduce power losses as well as electromagnetic emissions and immunity.

- Avoid running motor wires in parallel with other wires for long distances, especially feedback and signal wires.

- The parasitic capacitance between motor wires should not exceed 10 nF. If very long cables (> 100 meters) are used, this value may be higher. In this case, add series inductors between the Titan Go outputs and the cable. The inductors must be magnetically shielded, and must be rated for the motor surge current. Typical values are around 100 μH.

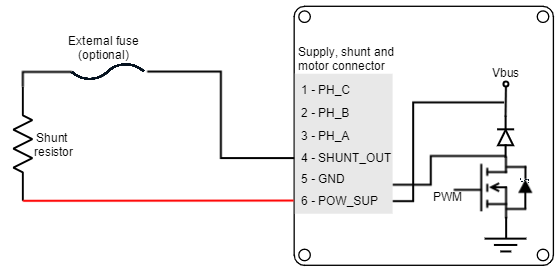

Shunt braking resistor

While decelerating a motor (abrupt motion brakes or reversals), the mechanical energy is converted into electrical energy by the motor. This energy is regenerated into the power supply and could lead to an increase of the supply voltage. To absorb this energy the Titan Go incorporates a shunt transistor to connect an external braking resistor.

Wiring recommendations of the shunt braking resistor:

- The external braking resistor should be connected between SHUNT_OUT and POW_SUP terminals of the Titan Go Supply and shunt connector.

- It is strongly recommended to use an external fuse to limit the maximum power dissipation according to the chosen shunt resistor.

- Wire section should be, at least, like the motor wires.

- Shunt resistor connections should be as short as possible to reduce parasitic inductances.

Shunt resistor calculation tool

Additional information on shunt braking resistor sizing and a calculation tool can be found here.

Hot surfaces

Be careful, shunt resistor may have hot surfaces during operation.

Configuration of the shunt

The shunt transistor can be configured using parameters in the register 0x2103 - Shunt configuration. When the supply voltage reaches the maximum voltage indicated in register 0x2101 - Drive bus voltage, the shunt transistor is activated.

As a recommendation, set the DC bus voltage limit above the maximum expected DC supply voltage + 5%.

When using batteries, set the DC bus voltage limit below the maximum charge voltage. This will allow regenerative braking and protect the battery against overcharging.